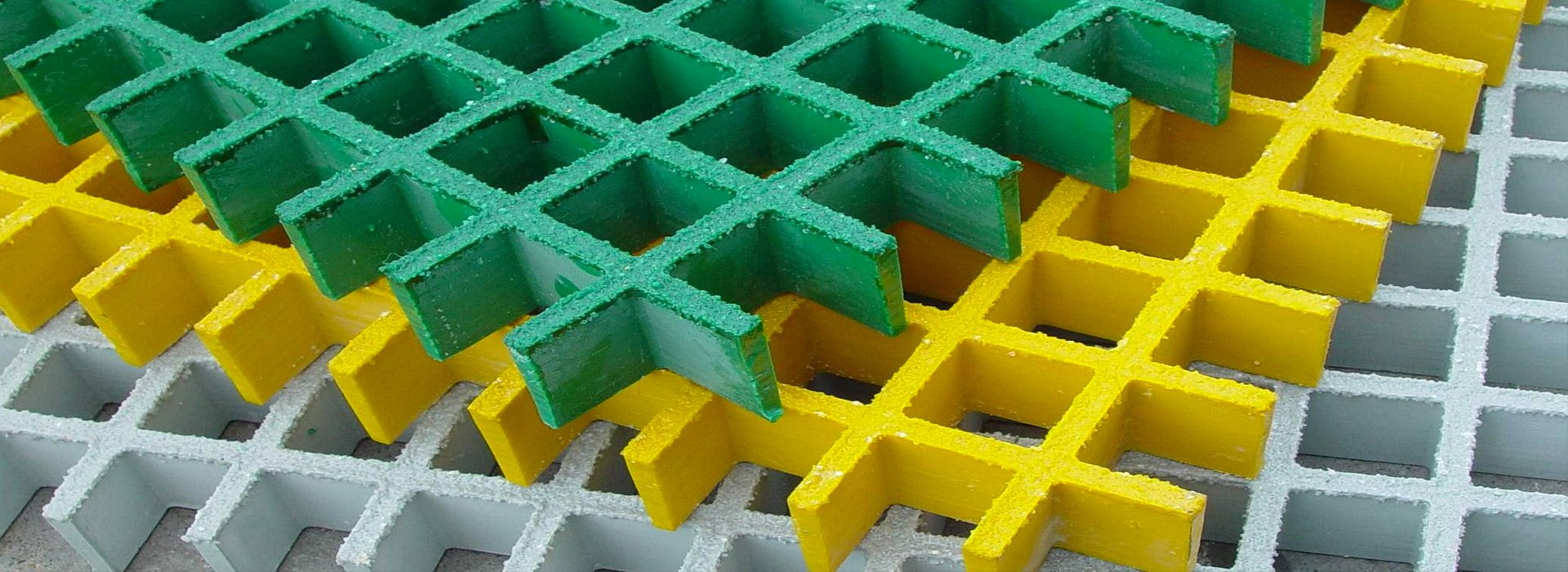

Fibreglass gratings are pultruded composites made from polyester resin (orthophthalic), vinyl ester and phenolic resin. We use these three different types to obtain profiles with different levels of resistance to high temperatures or to corrosive chemicals. They can be used in a range of manufacturing sectors, including transport and public transit in general, through to the petrochemical industry.

Product features

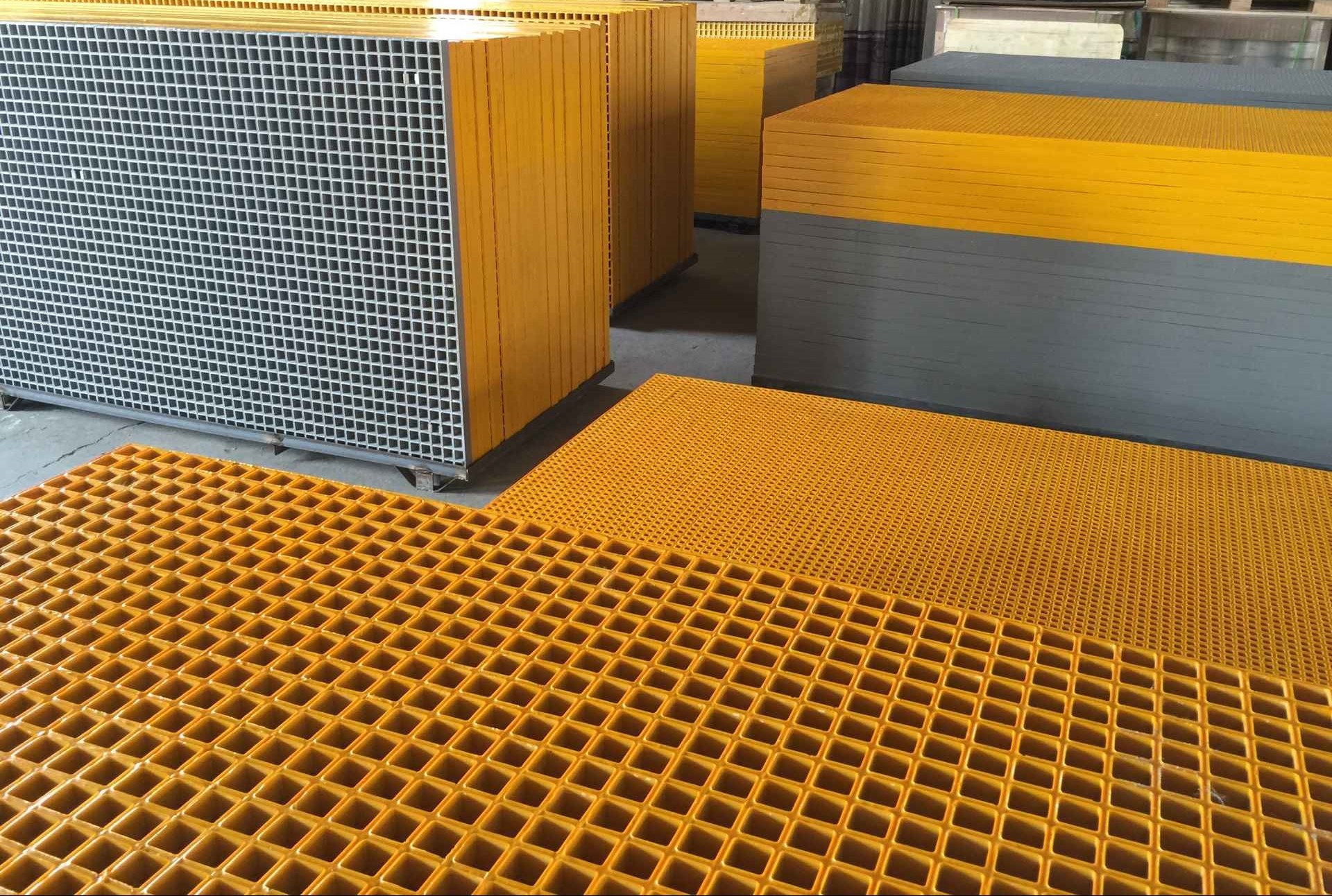

Our fibreglass gratings are made from pultruded profiles. These composites are gaining ground very quickly and are being chosen over steel products more and more often.

They stand out because they are versatile, corrosion-resistant, electrically and thermally nonconductive, light and their structural features are comparable to steel.

These pultruded profiles have very low maintenance costs and they do not need coating or galvanising before use. They can be cut or drilled directly on site using the most common cutting or drilling tools and do not require any special training or expertise to be handled or modified.

The fibreglass gratings manufactured by Saimex s.r.l. also have an extra feature: in order to make sure the resin is protected against ultraviolet light, we add additive UV-9 to the resin itself. This excellent sunscreen is one of the most advanced of those developed by the polymer industry. On the one hand, it guarantees that the composite materials are enduring and, on the other, that the resin preserves its mechanical properties.

Fields of application

The structural characteristics of our fibreglass gratings, their corrosion and heat resistance, and their impact strength make them very versatile for use in a number of different industrial and manufacturing sectors.

In particular, we recommend their use in highly corrosive environments such as chemical plants, marine and other wet environments, in the transport and public transit sector, and in the cooling towers and offshore platforms of the oil industry.

Saimex s.r.l. manufactures high quality fibreglass gratings and is formed of a team of specialist design engineers who continue their research into increasingly high-performance solutions.