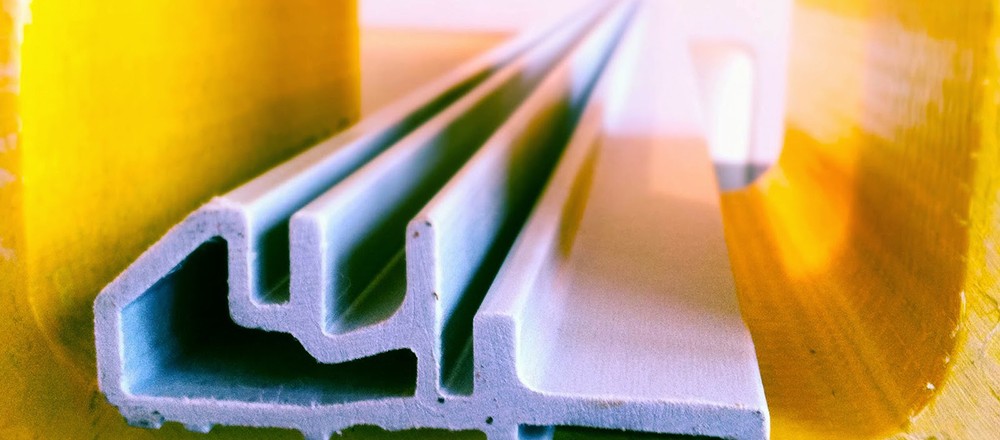

Pultruded profiles have been started to be used in the building sector for some time now, but also for the construction of infrastructures related to the oil and railway sector. Steel has been replaced by pultruded profiles, because their durability is longer, but also for whatever it may concern the lightness, the aesthetics and ease of management on the construction site. In this regard, it is good to specify something in relation to the cut mode of pultruded profiles.

When working on a construction site and there is the need of manipulating a pultruded profile by cutting or boring it, the reference to be considered are diamond blades. Having said this, a basic specification is necessary to understand how is it possible to handle pultruded profiles in practical terms and exploit all the advantages compared to steel, we can go deeper into the details of other technical specifications, by pointing out that pultruded profiles can’t be neither bent nor curved.

With a sigma under tension corresponding to 240 Mpa, pultruded profiles have been designed for specific calculation programs, always starting with orthotropic data. When speaking about technical features of pultruded profilesand cutting mode it’s important to remember their resistance when using diamond blades. At this regard it is possible to make reference to data corresponding to 3000 Mpa.

The pultruded profile is a brittle material for all intents and purposes,but able to withstand extreme temperatures. In this case it’s possible to have a range included between – 40°C and +180°C. When taking into consideration the thermal insulation, a peculiarity that determines the success of pultruded profiles compared to steel, it is possible to gain a full picture describing the revolution that the pultruded profile has been brought to many sectors with considerable advantages both for the work of designers and for the end user who has to bear the costs and for the environment.

Read More