Pultruded materials present remarkable features. Even though Saimex Srl is already operating under certified conditions, it was decided to further test the capacity of their product. Therefore, flexural and pull tests were commissioned to the Technical University of Milan and performed by a technology bearing the company’s logo: Deck System, a special deck in composite material, which is light and extremely versatile. Its applications range from pedestrian bridge to pedestrian paths.

Flexural test

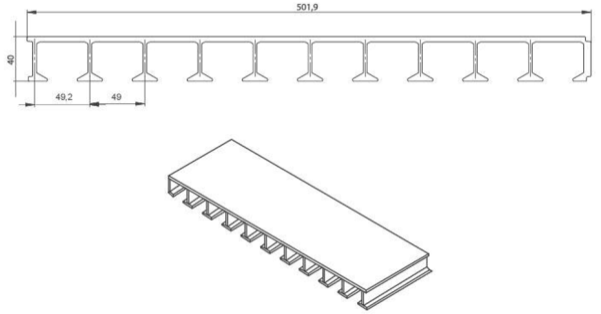

It was performed on sampled panels Deck System HD supplied by Saimex Srl. The single elements had the following sizes: 501.9 mm x 1,800 mm x 40 mm (Figure 2).

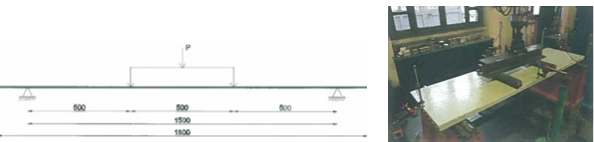

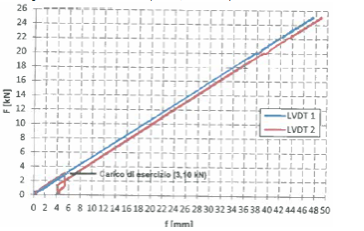

The promotion campaign has planned to perform three flexural load-controlled tests in a four-point static scheme and a clear distance between the supports of 1,500 mm (Figure 3). The purpose of this test is to verify if the elements are shifted towards the mid-span using the working load.

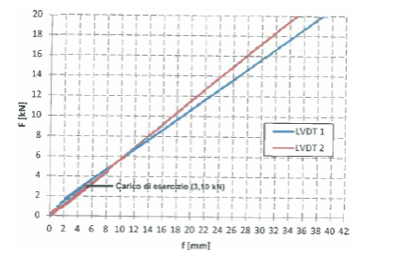

Test no. 1:

– maximum deflection limit per working load Pe = 3.10 kN kept for 10 minutes: 7 mm;

– maximum load applied: Pu = 20 kN

Results:

- no breakage or failure due to Pu;

- minimum residual deformation of post-discharge (u = 0.940 mm).

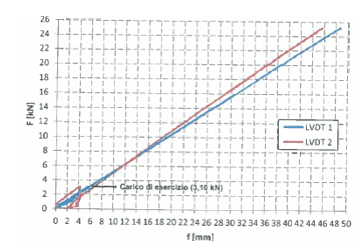

Test no. 2:

– maximum deflection limit per working load Pe = 3.10 kN kept for 10 minutes: 7 mm;

– maximum load applied: Pu = 25 kN

Results:

- no breakage or failure due to Pu;

- minimum residual deformation of post-discharge (u = 1.759 mm).

Test no. 3:

– maximum deflection limit per working load Pe = 3.10 kN kept for 10 minutes: 7 mm;

– maximum load applied: Pu = 25 kN

Results:

- no breakage or failure due to Pu;

- minimum residual deformation of post-discharge (u = 1.790 mm).

The maximum arrows were reached at mid-span for a maximum load applied respectively in all the three tests and are, as follows:

| Test no. | fmid-span [mm] |

| 1 | 5,221 |

| 2 | 5,015 |

| 3 | 5,562 |

Table 1: maximum mid-span deflection of the samples

Therefore the tests give evidence to the considerable ability of Pultruded composite materials produced by Saimex Srl, which not only confirm, but also overcome by far the expectations of the Technical University of Milan and of the company and the values prescribed by the current regulations relating to composite materials (UNI EN 13706).

[Coming up the second part of ‘Mechanical testing of pultruded composite materials’]