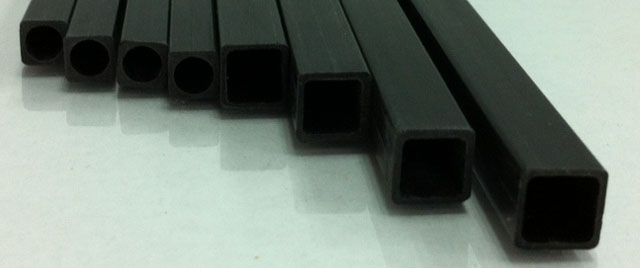

‘Structural pultruded profiles’ are made of composite materials, obtained using the pultrusion technique. These particular composite materials consist of synthetic organic resins and usually glass fiber.

The pultruded fiberglass profiles are composed of long fibers and mats which are also called Fiber Reinforced Polymers orFRP; Glass Fiber Reinforced Polymer (GRFP) in the case of glass fibers and Carbon Fiber (CF) in the case of carbon fibers.

Fiberglass pultruded profiles: the advantages

The pultruded fiberglass profiles are to be preferred to traditional steel and aluminum profiles for several reasons and some of the major properties are as follows:

- Light weight

- High corrosion resistance

- Dielectric strength

- Thermal insulation

The composite materials, made of polyester resins are, in fact, about 70% lighter than steel. They also ensure resistance to corrosion from various atmospheric agents and are completely immune to electromagnetic interference.

Furthermore these are other advantages offered by pultruded profiles:

- Low thermal conductivity

- Thermal stress resistance and expansion

- Excellent bump resistance

- Excellent mechanical resistance

As you can see, the use of composite materials is recommended especially in the civil and industrial industry due to all problems related to corrosion and electromagnetic interference. In addition benefits in terms of significantly lower maintenance costs should not be underestimated. Another big advantage of structural pultruded profiles is offered during the panel assembly in terms of a major time-saving.