[To be continued…]

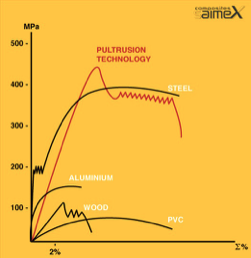

The overall mechanical behavior shows elastic-brittle features until reaching an ultimate strength and, therefore, a sudden collapse without further deformative contributions.

Figure 1 – A comparative stress-strain graph (www.saimex.it)

Features and advantages:

- lightness;

- high mechanical resistance;

- thermal insulation/thermal break;

- fire-resistant;

- recommended maximum operating temperature 60°÷90° (using high-performance resins);

- maximum temperature range – 40°C ÷ 180°C;

- corrosion resistance;

- maintenance-free;

- radiolucent;

- profiles based on customer’s drawings.

If the temperature range is low, the pultruded material doesn’t show any decay of mechanical performance; on the contrary it is possible observe an increase in the strength parameters.

The material leaves a wide margin of designing in relation to its thermal and electrical properties; the longitudinal extension in the direction of fibers is limited, whereas the same doesn’t happen along the two transverse directions. The material takes on a similar behaviour, even when the thermal conductivity is concerned with small changes depending on the fiber used. The response to electromagnetic stresses is on the whole good, although it is rather moderate against the carbon fiber composite materials.

Hereunder you find a comparative table of the key features of Pultruded Materials and of the major competitive materials:

| Properties | Pultruded Material | Steel | Aluminium | PVC |

| Density [g/cm3] | 1.8 | 7.8 | 2.8 | 1.4 |

| Tensile strength [MPa] | 350 – 400 | 370 – 500 | 200 – 400 | 40 – 60 |

| Pull elongation [%] | 1.5 – 2.0 | 13 – 35 | 5 – 35 | 10 – 80 |

| Flexural strength [MPa] | 400 – 450 | 330 – 500 | 200 – 400 | 70 – 100 |

| Elastic modulus [103 MPa] | 25 – 30 | 210 | 70 | 2.8 – 3.3 |

| Flexural modulus |

[103 MPa]15 – 20210702.8 – 3.3Impact resistance [MPa/m2]20040020085 – 95Thermal conductivity [W/m°C]0.25 – 0.35100 – 230100 – 2300.15 – 0.25Coefficient of thermal expansion [106 MPa/m°C]5 – 2010 – 1420 – 2550-100Dielectric capacity [KV/mm]5 – 15–40 – 50Volume resistivity [wcm]1010 – 10140.2 – 0.80.028> 1016

Table 1 – comparative table of mechanical features of materials under consideration (www.saimex.it)

[Coming up ‘Tests performed at the Technical University of Milan’]

Read More