The Saimex Srl company specializes in the production and sale of structural profiles in composite material – Wood Fiber and Glass Fiber – and in particular in the production of THRESHOLDS and parts of windows in FIBERGLASS, exploiting the properties of the material of thermal insulation (lambda value (λ) = 0.25) and resistance to loads up to 1000 kg.

Saimex profiles, thanks to their insulating structure due to the composite material they are made of and the thermal break, are used as thresholds for tile-and-slide systems and as structural parts of windows and doors.

We are one of the leading manufacturer companies of GLASS FIBRE THRESHOLDS for WINDOWS for the most important European brands.

CHARACTERISTICS OF FIBREGLASS THRESHOLDS

Among the main features of Saimex fiberglass THRESHOLDS:

• Thermal insulation

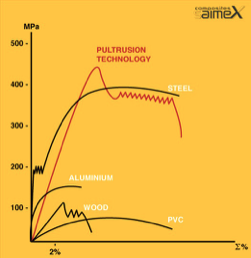

• Mechanical properties comparable to steel

• 100% waterproof

• Total absence of maintenance; since Saimex thermal break windows and doors are resistant to the outside, it guarantees less maintenance costs on the final product.

• High resistance to corrosion and sea water

• Resistance to salt mists

• Anti-condensation

With Saimex fiberglass profiles it is also possible to prevent or eliminate thermal bridges.

CUSTOMIZATION

The company Saimex srl is also highly specialized in the realization of COMPLEX SECTIONS AND CUSTOM PROFILES, and we will be happy to give you support with your projects.

Saimex s.r.l. has in fact a technical office always available to listen and meet your needs. Our team of engineers has a long experience in the design and structural calculation of fiberglass profiles for windows and thresholds for sliding windows.

We have also developed a type of smooth surface finish that does not require further coating, or the application of a protective film and we offer the possibility to choose from a wide range of RAL colors and metallic colors.

ENERGY SAVING

Thanks to the thermal properties of composite materials, the doors, windows and thresholds for tile-and-slide systems in fiberglass are important for the energy insulation of homes and buildings and for the Casaklima project which allows buildings to save energy (by reducing consumption) and economical to sustain themselves.

Read More