In recent years, the features of composite materials and their manufacturing processes have undergone considerable development to obtain structural products and to investigate the sectors and application fields where they can be used. One manufacturing process which gave the best performance results is pultrusion.

Pultrusion

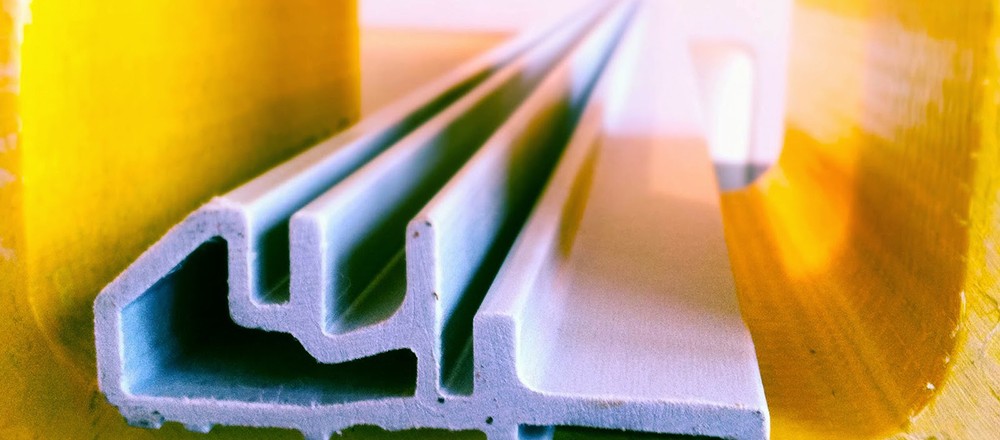

Pultrusion is a continuous process of composite materials reinforced with fibreglass or carbon fibre. Consist in the extrusion of profiles with a constant cross-section which is continuously pulled in a closed mould polymerisation. The pultrusion process produces profiles that sometimes give greater guarantees than those made of steel and stainless steel.

The process is developed in three fundamental steps:

- The reinforcement fibres are carefully positioned in a pre-mould according to the structural requirements of the final pultruded profile;

- The fibres are impregnated in an open tank and then carried to a precision steel mould. The fibres can be impregnated directly in the closed mould using a direct injection system;

- The mould is heated using a computerised system which controls the polymerisation process and monitors the advance speed of the pultruded material;

- The profile comes out of the mould and is ready for cutting.

The reinforcement fibres are arranged longitudinally and are made up of complex roving systems and glass or carbon or Kevlar fibres. They make up about 70% of the profile and determine its tensile and flexural strength.

Pultrusion features and advantages

The pultrusion process guarantees the customisation and the repeatability and perfect reproducibility of each product. Although the manufacturing process is still quite slow, the energy consumption required is lower than that required to produce the same aluminium profiles.

Fiberglass pultruded and carbon profiles are environmentally friendly, resistant to rust and corrosion and once implanted in soils or near groundwater they do not release toxic substances.

If you want to learn more about the features of this working process, contact us and we will lead you to the discovery of pultrusion and pultruded profiles in fiberglass and carbon fibre.

Read More

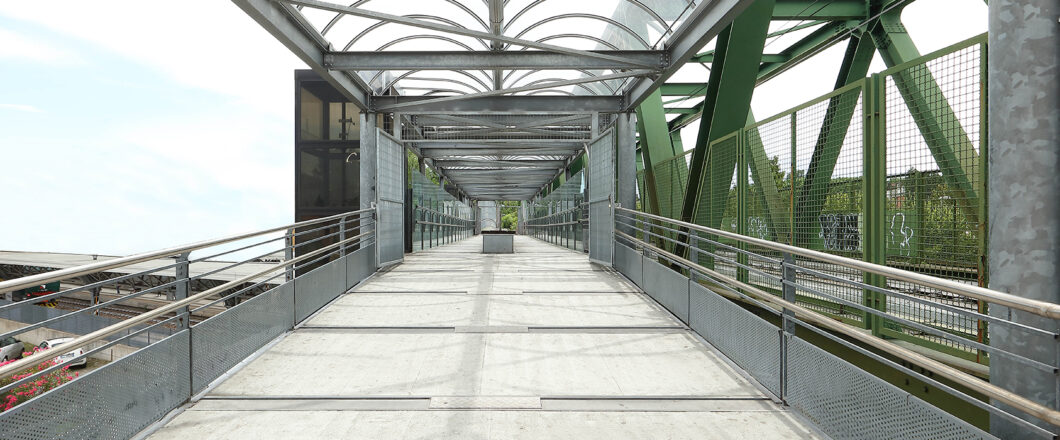

The FIBRA deck system, consisting of interlocking pultruded staves reinforced with glass or carbon fibres, is used in the railway industry for the construction of pedestrian areas of bridges, self-supporting walkways and floors for chemical plants.

What are the advantages?

- Excellent durability over time

- Faster assembly times compared to traditional materials

- Resistance to corrosion and water

- Ultra-lightness

- Easy workability and maintenance-free

- Excellent thermal insulation

We also produce an anti-slip version to improve walking.

FIBRA profiles by Saimex win out over profiles made of steel, aluminium, PVC and other materials under special conditions. The uses of FIBRA in the railway sector are for electrical cable ducts, handrails, electrically insulated walkways, gratings, posts, brackets, trusses and panelling.

In the railway sector, it is widely used thanks to its features:

- easy workability and maintenance-free

- ultra-lightness and tensile strength

- resistance to corrosion and moisture

- electrical, fire and smoke resistance

We also offer an additional cutting, mechanical machining and painting service.

Read More

It is people, their skills and their dedication that determine the value of a company, which is why Saimex decided to organise three days dedicated to playful, experiential and educational activities that confronted the team with the need to overcome obstacles, to challenge themselves and to find an optimal combination of resources within themselves.

“It was a different experience than usual, allowing us to understand that collaboration leads to the achievement of great goals“, “three meetings focused on different topics that strengthened team spirit” said some of the Saimex employees.

The teambuilding was an important opportunity to share values, visions and strengths, which have contributed to the group’s steady growth aimed at ensuring the best for our clients.

Read More

We are an Italian company specialised in the design and production of fibreglass thresholds. We also have 5-axis CNC machines capable of handling profiles up to 7 metres long and cutting, trimming and drilling operations.

The window and door industry is increasingly looking for innovative materials that guarantee thermal break and structural capacity, but without sacrificing aesthetics.

Our FIBRA thresholds, manufactured by extrusion process, have the following characteristics:

– THERMALLY INSULATING

– MECHANICAL PROPERTIES COMPARABLE TO STEEL

– TOTALLY MAINTENANCE-FREE

– 100% WATER-RESISTANT

– HIGHLY RESISTANT TO CORROSION AND SEAWATER

– LOAD CAPACITY UP TO 1000 KG

– AVAILABILITY IN DIFFERENT COLOURS

Discover the variety of thresholds we produce here on our website or write us at info@saimex.it

Read More