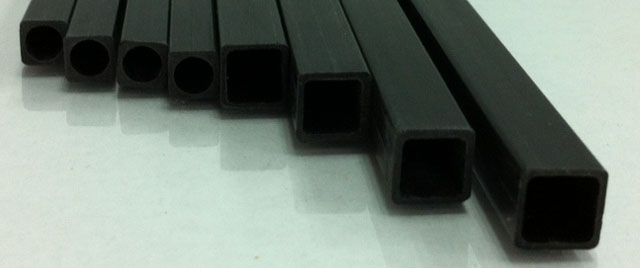

Saimex s.r.l. is located in Seregno, the Italian province of Monza e Brianza, and manufactures high and medium strength structural pultruded profiles and bars in composite materials of organic resins reinforced with glass or carbon fibres. This blend of constituent materials provides superior qualities that make for a particularly high-performance product to be used in a number of different production sectors, as an alternative to the traditional models. Our pultrusion process means we can obtain a wide variety of profiles for our extensive catalogue listings, supplemented by custom profiles made to meet the needs of the client. The Brianza-based company also manufactures other parts for use in a wide range of applications and production areas.

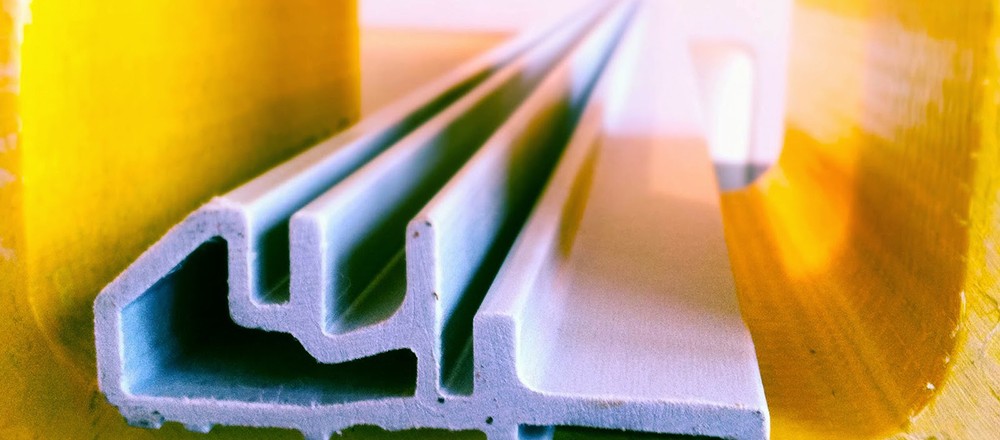

Resin sheet piles

The Saimex catalogue of innovative solutions is very extensive and also includes the manufacture of resin sheet piles, which are being widely used to replace traditional sheet piling. These elements are very important in constructions because they are required to guarantee support and containment.

Developed and manufactured to the most innovative design standards, processing of this kind makes it possible to achieve excellent performance and tightness, with the added advantage of being very light, even on contact with water. At Saimex, we are well aware of the benefits of these constituent materials, which is also why we have entered into a partnership with the IUAV University in Venice to complete a study listing the functional qualities of the pultruded sheet piles in glass fibre, including the fact that our fibreglass sheet piles are up to five times lighter than steel piling.

One advantage of this is a drop in transport costs. Not only that but the composite fibre and carbon materials will not corrode even in contact with water.

The ideal applications for these kinds of sheet piles include the building industry and infrastructures, and our sheet piles are also part of the MOSE flooding protection system in Venice. What’s more, we have developed two different models: Heavy Duty Sheet Piling which can be sunk down to more than 12 metres, and has the same characteristics as steel, and Light Duty Sheet Piling which can be sunk down to 6 metres and replaces wood and PVC piles to create attractive barriers.

IPE double flange beams

We manufacture fibreglass double flange beams that very effectively develop the characteristics of our structural pultruded profiles.Their double-T shape improves elasticity, making them stable even when placed in torsion and as a result they are particularly suitable for large structures.

These elements can be used for a wide range of different applications, including, in addition to the construction and transport industries, the chemical and physical sector and doors & windows and outside walls, with the proposal of products such as the Isoldeck paving system, gratings, handrails and floorboards, and roof and skirt panels.

Read More